Business

Leading the Way in the Bioindustry, BIOSREAM

헬스케어

HEALTHCARE

- Biostream Eumseong Campus

-

Based on years of technology and know-how, Biostream is

ISO9001 certified and GMP certified, and has built state-of-the-art

manufacturing plants and facilities in Eumseong Campus.

- Destination

- 120, Seongbonsandan 1-ro, Daesomyeon-si,

Eumseong-gun, Chungcheongbuk-do, Republic of Korea

- Gross Floor Area

- Gross floor area of 6,465.2m2 (1 basement ~ 3 floors)

Formulation

-

Tablets

Tablets -

Powder

Powder

Package

-

PTP

PTP -

Vials

Vials -

Stick Packages

Stick Packages

Certification Status

Facility Status

-

Clean Room SystemAll processes utilize a clean room system

to prevent external contamination and internal

cross-contamination, with strict control of

temperature, humidity, and cleanliness

throughout all areas. -

RO SystemWe use only purified water for washing and

manufacturing during tablet production to

ensure the highest product quality. -

High Rack SystemWe have implemented a High Rack System to

separate and store raw materials and products,

maintaining temperature and humidity while

effectively blocking external contaminants for

quality control.

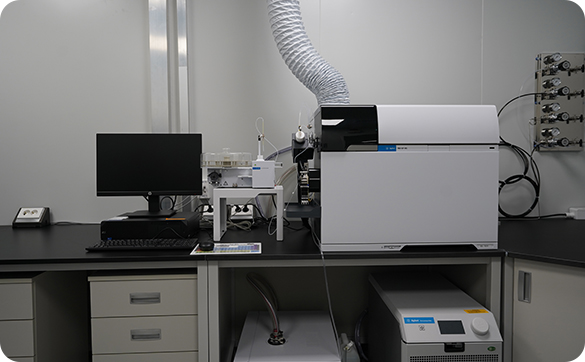

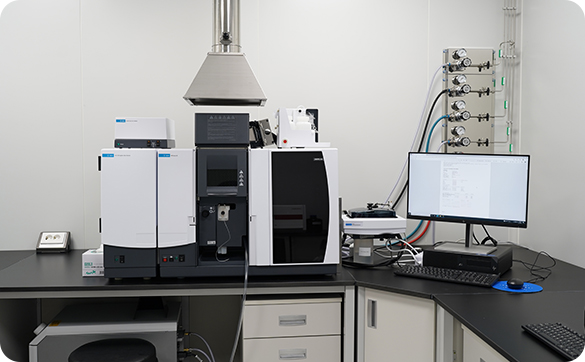

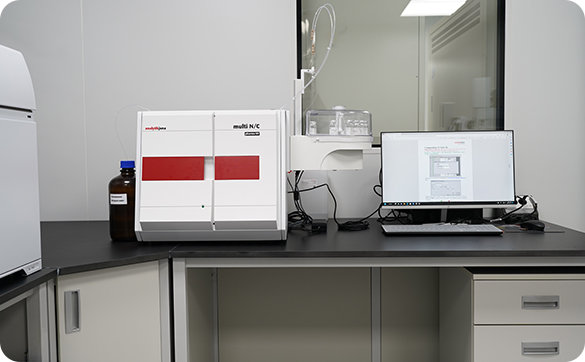

Facility Status

-

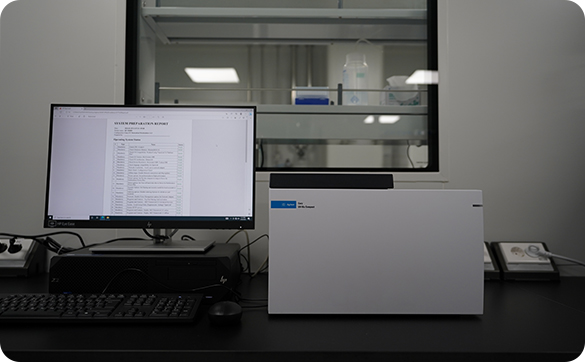

Chromatographic Component

Analysis SystemsLC/GC analysis system was introduced to precisely analyze the ingredients and their content in raw materials and products. -

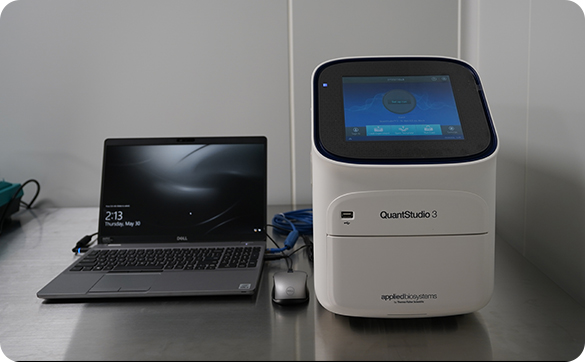

Metal Impurity

Detection SystemsAtomic Absorption Spectrometer (AAS), Infrared

Spectrophotometer (FT-IR), and ICP-MS,

which are essential for metal impurity detection,

were introduced to maintain the highest quality.